| Nº | Nome do equipamento | Unidade | Quantidade | Funções principais |

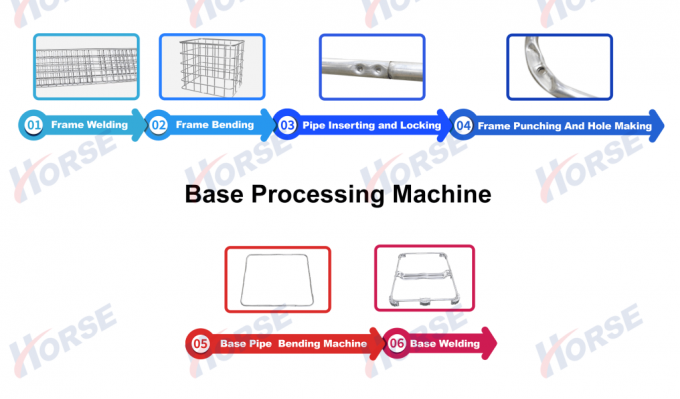

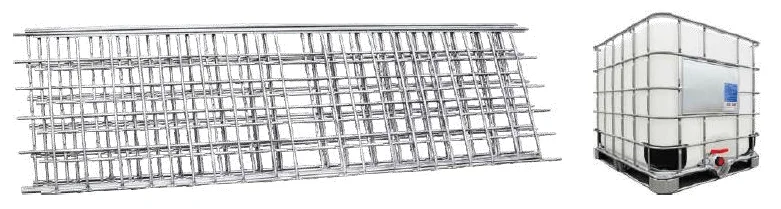

| 1 | Máquina de soldagem de pórtico de malha | Unidade | 1 | Soldagem multiponto de malha |

| 2 | Máquina de alimentação automática de malha | Conjunto | 1 | Carregamento automático de tubos longos e curtos |

| 3 | Manipulador de coleta de material de malha | Unidade | 1 | Descarga de malha (empilhamento) |

| 4 | Máquina de dobra de quatro eixos | Conjunto | 1 | Dobramento e formação de malha com cabeça de encolhimento |

| 5 | Máquina de travamento | Conjunto | 1 | Dobramento e intertravamento de malha |

| 6 | Máquina de perfuração de achatamento | Conjunto | 1 | Perfuração e corte do tubo inferior sob a estrutura |

| 7 | Manipulador de estrutura | Conjunto | 1 | Três manipuladores movendo-se para cima e para baixo para agarrar a estrutura |

| 8 | Máquina de soldagem de pés de aço | Conjunto | 1 | Soldagem dos pés de aço da estrutura inferior |

| 9 | Manipulador de coleta de material da máquina de soldagem de pés de aço | Conjunto | 1 | Retirada, transferência e empilhamento da estrutura inferior após a soldagem |

| 10 | Máquina hermética automática | Conjunto | 1 | Testando a estanqueidade do revestimento |

| 11 | Máquina de dobra dupla automática para tubo inferior | Conjunto | 1 | Encolhimento, gravação e dobra do tubo inferior |

| 12 | Plataforma de teste de vibração | Conjunto | 1 | Testando a firmeza e proteção dos barris IBC |

Deixe um recado

Ligaremos para você em breve!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Submeter

Mais informações facilitam uma melhor comunicação.

Senhor

- Senhor

- Senhora

Está bem

Submetido com sucesso!

Ligaremos para você em breve!

Está bem

Deixe um recado

Ligaremos para você em breve!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Por favor verifique seu email!

Submeter